2 Helical Hole 40 Degree H6 Tolerance

2 Helical Hole 40 Degree H6 Tolerance

Product specifications

Features

A. Threaded carbide rod with holes are mainly used for processing tungsten parts or as a tool bit of processing lathe, conductors, steel-making burdening and additives;

B. They are also applied in crankshaft, cylinder burdening and electrodes for advanced automobiles;

C. They are also produced as components for manufacturing of artillery, rockets, satellites, aircrafts and ships. In addition, helical coolant ducts can be also used as radiation-proof material in nuclear industry.

Specification

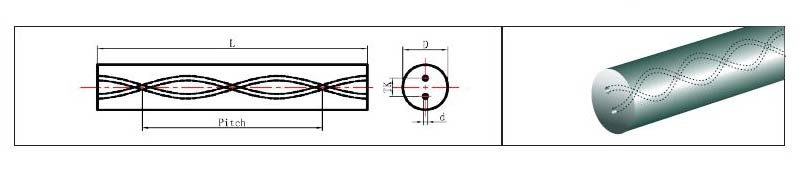

Precision Ground Rod, 2 Helical Hole 40 degree

Type: R2H40

Metric Sizes 6mm to 20mm Diameter h6 tolerance

| Item No. | OD | Tol. h6 | L | Tol. | TK | Tol. | d | Tol. | Pitch |

|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| R2H40-0600-3300PG | 6 | 0/-0.008 | 330 | 0/+5 | 2.0 | ±0.15 | 0.5 | ±0.1 | 22.46 |

| R2H40-0800-3300PG | 8 | 0/-0.009 | 330 | 0/+5 | 2.4 | ±0.30 | 0.65 | ±0.15 | 29.95 |

| R2H40-1000-3300PG | 10 | 0/-0.009 | 330 | 0/+5 | 3.1 | ±0.40 | 0.8 | ±0.15 | 37.44 |

| R2H40-1200-3300PG | 12 | 0/-0.011 | 330 | 0/+5 | 3.8 | ±0.40 | 0.9 | ±0.15 | 44.93 |

| R2H40-1400-3300PG | 14 | 0/-0.011 | 330 | 0/+5 | 4.3 | ±0.40 | 1 | ±0.2 | 52.42 |

| R2H40-1600-3300PG | 16 | 0/-0.011 | 330 | 0/+5 | 5.1 | ±0.40 | 1.2 | ±0.2 | 59.9 |

| R2H40-1800-3300PG | 18 | 0/-0.011 | 330 | 0/+5 | 5.9 | ±0.40 | 1.4 | ±0.25 | 67.39 |

| R2H40-2000-3300PG | 20 | 0/-0.013 | 330 | 0/+5 | 6.6 | ±0.50 | 1.5 | ±0.25 | 74.88 |

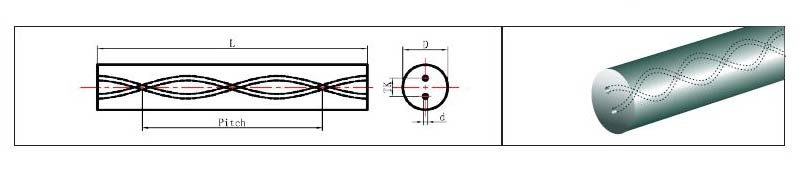

Unground Rod, 2 Helical Hole 40 degree

Type: R2H40

Metric Sizes 6mm to 20mm Diameter

| Item No. | OD | Tol. | L | TOL | TK | TOL | d | TOL | Pitch |

|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| R2H40-0630-3300UG | 6.3 | +0.3/+0.7 | 330 | 0/+5 | 2.0 | ±0.15 | 0.5 | ±0.1 | 22.46 |

| R2H40-0830-3300UG | 8.3 | +0.3/+0.7 | 330 | 0/+5 | 2.4 | ±0.30 | 0.65 | ±0.15 | 29.95 |

| R2H40-1030-3300UG | 10.3 | +0.3/+0.7 | 330 | 0/+5 | 3.1 | ±0.40 | 0.8 | ±0.15 | 37.44 |

| R2H40-1230-3300UG | 12.3 | +0.4/+0.9 | 330 | 0/+5 | 3.8 | ±0.40 | 0.9 | ±0.15 | 44.93 |

| R2H40-1430-3300UG | 14.3 | +0.4/+0.9 | 330 | 0/+5 | 4.3 | ±0.40 | 1 | ±0.2 | 52.42 |

| R2H40-1630-3300UG | 16.3 | +0.4/+0.9 | 330 | 0/+5 | 5.1 | ±0.40 | 1.2 | ±0.2 | 59.9 |

| R2H40-1830-3300UG | 18.3 | +0.4/+1.0 | 330 | 0/+5 | 5.9 | ±0.40 | 1.4 | ±0.25 | 67.39 |

| R2H40-2030-3300UG | 20.3 | +0.4/+1.0 | 330 | 0/+5 | 6.6 | ±0.50 | 1.5 | ±0.25 | 74.88 |

Added to cart

Added to cart